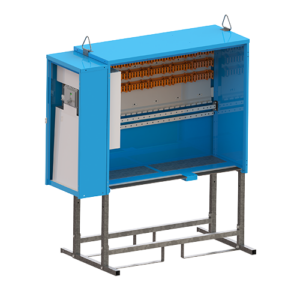

Revolutionary power distribution products, adaptable to suit your business needs.

Efficient climate control with our smart heating and cooling solutions in any environment.

El-Björn produces efficient, versatile dehumidifiers for construction and textile drying.

Choose eco-friendly, quality energy solutions for efficient heating and cooling across the UK.

Power to Control Your Climate

Sustainable power and climate control solutions for UK purchase or hire

Our Services

BUY ONLINE

We have a wide variety of products available to buy online. We guarantee efficient delivery and provide installation advice to ensure a smooth process.

FEATURED PRODUCTS

We have a wide variety of products available to buy online. We guarantee efficient delivery and provide installation advice to ensure a smooth process.

UK WIDE RENTAL

We offer temporary solutions for a range of industries. From lighting, temperature contol, power supply and drying solutions. A simple process in the hands of our expert team.

Talk to Us

Call with your requirements on

(+44) 1483 729348

Or contact us online HERE

Survey

We'll carry out a survey and send you a detailed, competitive quote.

Installation

Our experienced team will deliver and install based on the specification

Support

Technical support and excellent aftercare is available should you need it.

Why El-Björn?

El-Björn’s power generation and climate control units provides the perfect solution for supporting a sustainable climate in your working environment. Our product range has been developed to maximize sustainability by focusing on energy efficiency, quality, and safety. Our climate control products includes units for heating, cooling, drying, dehumidification, and air movement.

UK WIDE RENTAL

We offer temporary solutions for a range of industries. From lighting, temperature contol, power supply and drying solutions. A simple process in the hands of our expert team.

Talk to Us

Call with your requirements on.

(+44) 01483 729348

Or Contact us online HERE

Survey

We'll carry out a survey and send you a detailed, competative quote.

Installation

Our experienced team will deliver and install based on the specification

Support

Technical support and excelent aftercare is available should you need it.